About

In June 2022, I will be a newly graduated Mechanical Engineer with my BSME. I plan to use this degree to pursue my passion for innovative technologies/products to increase universal accessibility across all industries. At the University of Washington, I have delved deep into the field of health and medicine, but I am excited to see where my degree will take me as I strive to do my part in creating a more accessible world.

During thorough exploration into the marriage between health and engineering, I have found a passion for accessibility. This passion has been applied to my academic curriculum as educator roles for incoming students and creating innovative designs to address existing needs in the health industry.

Projects that I have worked on focus primarily on medical device advancements. The considerations when designing for the user have allowed me to view engineering design in a different light. Compared to entering college with only a working knowledge of Microsoft Office Suite to my name, I have gained a lens of accessibilty and the skills to act on respective designs.

Experience

Technical: SolidWorks, 3D Printing (PLA, HTPLA, & PETG), MATLAB, FEA (ANSYS), Java, ME Machine Shop (emphasis on Lathe & Kneemill), Technical Writing, Microsoft Office Suite, Social Media Coordination.

Business: Team Leadership, Educator, Presentation (Individual & Group), Recruitment, Conflict Resolution, Professional Liason, Meeting Facilitator, Tradeshow Marketing & Networking.

Relevant Coursework @ UW: Introductory Biomechanics, Musculoskeletal Biomechanics, Vibrations, Advanced Energy Conversion Systems, Sensors & Instrumentation, Manufacturing Processes, Mechanical Design.

Projects

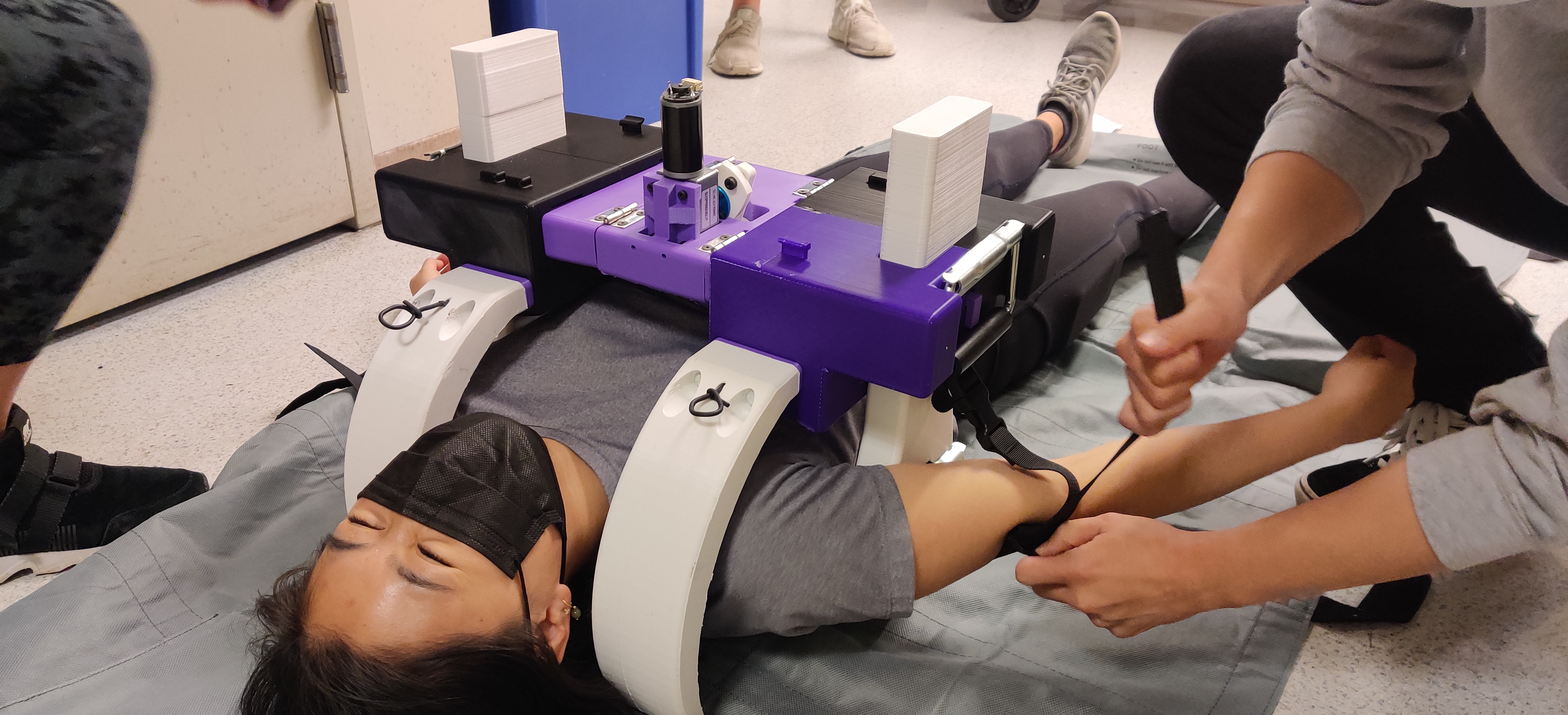

Mechanical CPR Device - UW EIH PushStart

Academic Year 2021-2022

Tools: SolidWorks Parts & Assemblies, Design for 3D Printing, 3D Printing (PLA & PETG), Small-Scale Assembly, Patent Filing, FDA Regulatory Processes, Business Plan Articulation.

Under remote mentorship from Philips, I collaborated with UW engineering students to design preliminary prototypes of a mechanical CPR device for first responders both in low-resource areas & while transporting out-of-hospital cardiac arrest victims. Designs were made with consideration for 3D printing and I printed multiple componenets of the device using both Ender3 Pro & Prusa printers with PLA, HTPLA, and PETG filaments. During multiple competitions, I delivered pitches to investors that awarded the project advancement in a business compeition and a finalist place in a health innovation challenge. I act as the liaison for external contacts, communicating via virtual meeting, email and phone. As such, I coordinated meetings with stakeholders to establish the identified need and issues with current solutions on the market.

Transtibial Socket & Pylon - BWB Prosthetics

Fall 2021

Tools: SolidWorks Parts & Assemblies, Design for 3D Printing, 3D Printing, Aluminum Machining, Laser Cutting.

I co-lead a group of undergraduate engineering students to create a transfemoral socket that is affordable, accessible, and adjustable. We compete annually at UW's Hollomon Health Innovation Challenge where we have been finalists two sequential years. Currently, we are working on cultivating a modular transtibial prosthesis (socket, shaft, and foot) in a virtual setting by way of 3D modeling and market analysis. As we gain access to campus, we have begun the physical prototyping process through intermediate machining

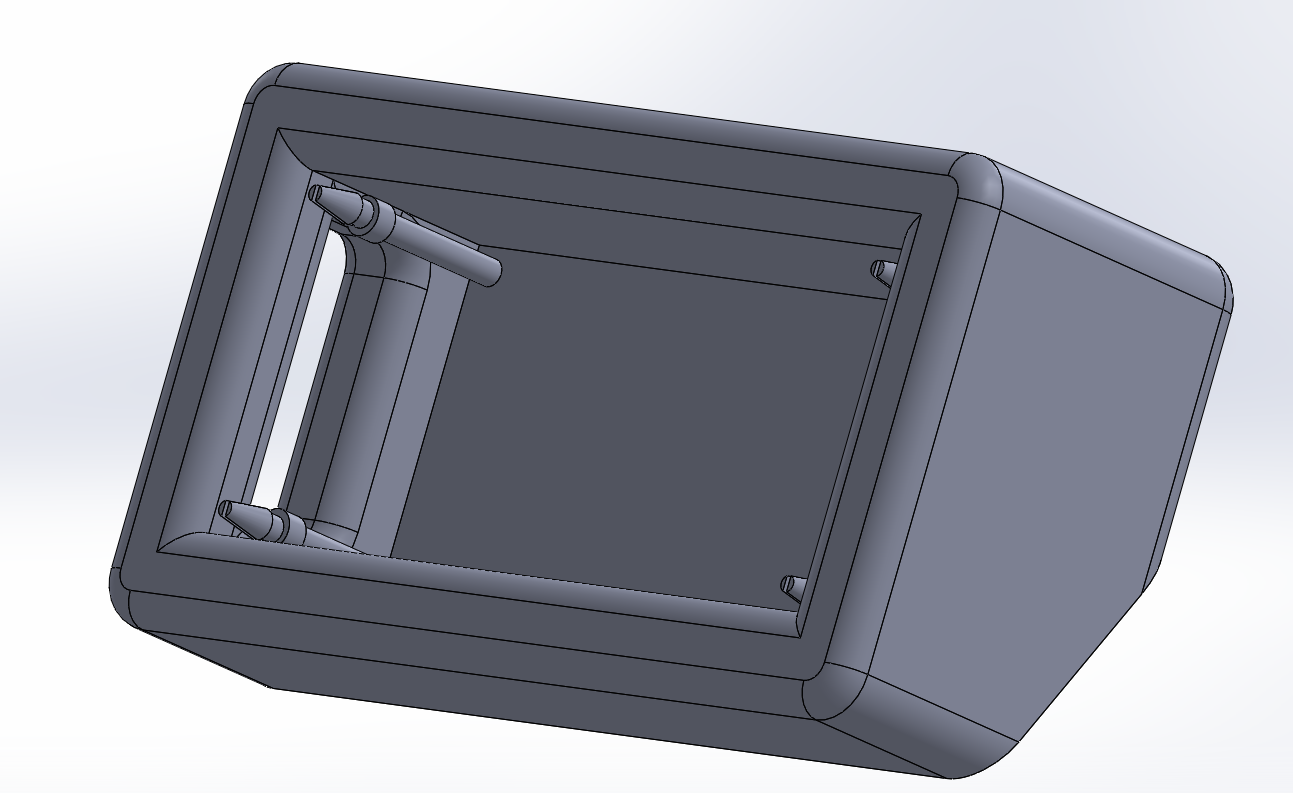

Monitor Housing - UW EIH Under Pressure

Summer of 2021

Assisted with clinical trials and refining a PPG- and ECG-based non-invasive, continuous blood pressure monitoring device that is compatible with existing operating room software (Philips IntelliVue MX800 monitors). I have assisted in researching data extraction techniques to allow patient data to be compiled into a database that is used to train a neural network that cleans the real-time blood pressure data. In presenting a final product, I designed, modeled, and 3D printed a housing for the complete system including an LCD screen that displays the continuous blood pressure reading & all hardware components.

Bicycle - LinkedIn Learning

Summer of 2021

Followed general instruction from a LinkedIn Learning course to design a realistic model of a bike. Customized the bike to personal liking using pre-existing SolidWorks knowledge and cycling experience to better emulate my personal bike.

Lawn Mower - UW Intro to SolidWorks Course

Spring of 2020

Tools: SolidWorks Parts & Assemblies, General Tolerancing & Fitments, Bill of Materials, Surface Finishing.

With an open ended assignment, I applied all of my knowledge from this course by both designing and modeling a lawnmower. It is based roughly on an existing Honda lawnmower residing in my parents' garage.